Digital connection technology

The idea of developing a Center for remote operational management is formed from the theory of “Internet of things” in the IR 4.0 and the actual production demand of Dong Nai Hydropower Company. The Company is currently managing two hydropower plants located about 45km apart and 100km far from the Company’s headquarter. The geographic distance and status of “separation in three places” has caused difficulty in the management and operation of plants. Therefore, the Company came up with the idea of “utilizing” two plants to be centralized in control at a single place - the Company’s headquarter.

Through the research, survey and selection of models, by 2017, the Company had successfully developed OCC Center with the principle of multi-dimensional connection on cyberspace. On the one hand, the Company has formed a connection between two separate plants, allowing the Center to visually monitor the equipment’s parameters, directly operate distance generating units. On the other hand, the Center has connected and received mobilization orders from the load dispatch centers for both plants, extending the connection of information on hydrographic reservoirs, electricity market, etc. All data is compatibly processed, logically displayed by the server system, significantly supporting the management and operation of the plants.

Mr. Pham Van Cuc - Director of Dong Nai Hydropower Company said that, in fact, the equipment of the plants was highly automated, technology infrastructure was basically invested. This is an advantageous basis for using digital technology in operation. In the development process of OCC Center, the most difficulty is to form and complete the idea. The Company has referred to the model of smart hydropower plants in the world, thus selecting the appropriate indicators to develop the control center in connection with the reality of Vietnam. The Company has also consolidated the system of optical fiber transmission infrastructure, forms an independent backup transmission line, particularly, provides the most reasonable security with multiple layers of information security, supporting for safe control of the units, contributing to ensuring the national energy security.

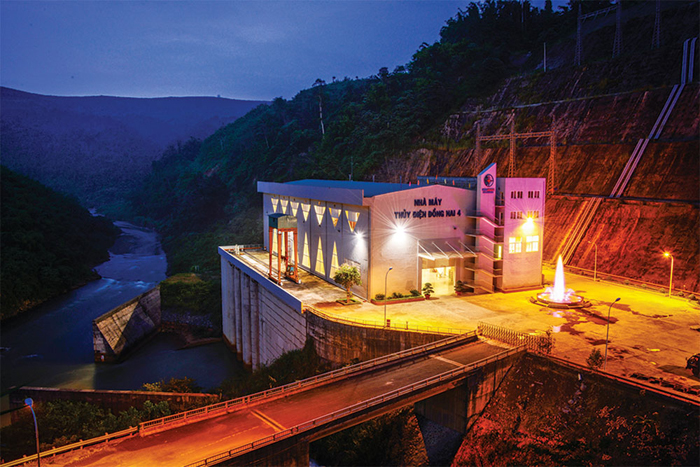

Dong Nai 4 Hydropower Plant – Photo credit: DVCC

Multiple purpose, multiple benefits

Currently, the OCC Center has been successfully commissioned and will be officially put into operation in the coming time. Hopefully, this is the crucial “hinge”, helping the Company to comprehensively innovate the model of operation, production, gradually adapting to the achievements of the IR 4.0. Currently, the Company has performed two separate duty shifts for operation, there will be only one remained at the OCC Center. Together with streamlining the overall operating apparatus, the Company can also optimize its human resources in operation. Instead of mobilizing 10 engineers for duty shifts of operation in the plants, it is now only requires the Company to assign about 3 to 5 people to master the remote control system. The duty shifts for operation at the plants will be just for monitoring and protecting the equipment.

Particularly, the OCC Center is expected to promote its crucial role, supporting the Company’s participation in the electricity market. Previously, the company’s decisions for price offering were often delayed due to strictly following the process of synthesizing information, reporting, waiting for decisions from leaders. Upon official operation, the OCC Center with the on-screen displayed parameters at the Company’s Office will help the leaders obtain information with the least possible delay, hence, making immediate decisions on price offering by every hour, significantly contributing to improving production and business performance.

In order to master the complex system and modern features, the Company has organized training on intensive profession for the team of operation engineers, developed the complete operation process, organized the exchange of experience with units inside and outside of EVN. At the same time, the Company also anticipates possible scenarios of incidents, thereby, conducts the handling drills and prepares the operating options.

In parallel with the preparation for official operation of OCC Center, Dong Nai Hydropower Company also has prepared a plan to set up a research team to improve the automation of the control system, reduce human manipulation on the system. Simultaneously, with the orientation to a smart OCC Center, the Company will also apply analytical algorithms to provide useful forecasts on load, intake water flow, price of electricity market; at the same time, form additional protocols connecting OCC system with other EVN’s softwares to share, optimize data as well as enhance the exploitation of features, meeting the increasingly modern procedures of production and business.

|

Dong Nai Hydropower Company:

- Headquarter: Bao Loc District, Lam Dong Province

- Management of 2 plants:

+ Dong Nai 3 Hydropower Plant: Capacity of 2x90MW, located in Quang Khe Commune, Dak Glong District, Dak Nong Province.

+ Dong Nai 4 Hydropower Plant: Capacity of 2x170MW, located in Loc Bao Commune, Loc Bac District, Lam Dong Province.

|

evn.com.vn

Share