Successful application of artificial intelligence in monitoring equipment of 220kV substation

17:36, 24/05/2022

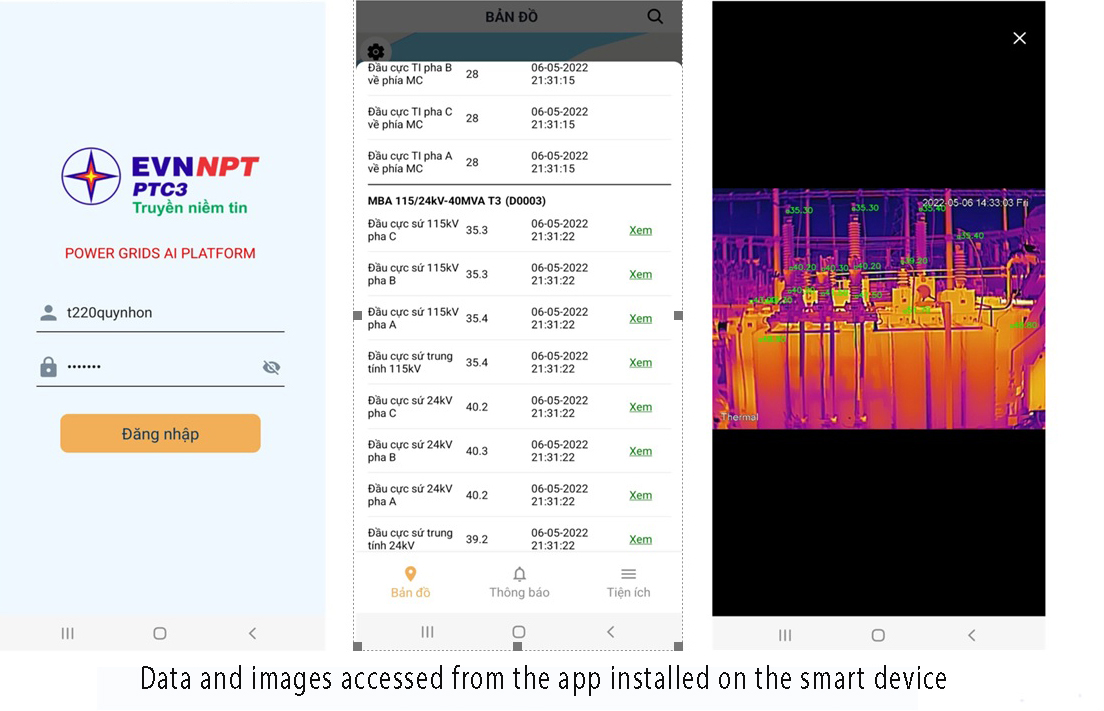

Power Transmission Company No. 3 (PTC3) has successfully tested the application of artificial intelligence (AI) in temperature monitoring of primary equipment and combined cabinets of 220kV substations. The early identification of abnormal factors helps the operator to make quick and accurate handling decisions; immediately prevent possible risks.

The connection capacity of renewable energy sources is increasing, causing the power grid in the South Central region and the Central Highlands, managed by Power Transmission Company No. 3 (PTC3), to regularly operate at full load and overload. In order to prevent problems, as well as reduce the load for workers operating in the condition of full load and frequent overload, PTC3 tested the application of artificial intelligence (AI) to monitor the temperature of the primary equipment and combined cabinets in 220kV substation (online temperature monitoring system with thermal cameras).

Currently, the temperature of the primary equipment and the combined cabinet of the Quy Nhon 220kV substation is monitored 24/7. The data is stored on the server, which can be retrieved as an Excel file or retrieved in the form of a chart, giving users an overview of the operating status of the device. The early identification of abnormal factors helps the operator to make prompt and accurate handling decisions.

Temperature monitoring data is also an important input criterion to properly assess the operating status of equipment, thereby deciding to perform repair and maintenance of equipment according to condition-based maintenance (CBM).

According to the assessment by PTC3, the online temperature monitoring system with thermal cameras for substations is an advanced and effective solution. With optimal investment costs, easy installation and operation, without affecting the operating equipment at the substations, helping the operator to more proactively perform the management and periodic inspection.

This application also handles many disadvantages of other traditional temperature monitoring systems such as: allowing continuous monitoring and warning, anytime, anywhere; continuously monitoring and storing data, so that the operator can monitor temperature changes in sensitive points in the substations. Along with that, the operator can identify the contact positions that are being monitored and can view visual images. The application can be connected to the SCADA system, acting as an IEC 60870-5-104 master/slave for data transmission, recording and saving data continuously as a basis for evaluation, analysis and research for proper operation.

evn.com.vn

Share