Identify causes to deliver solutions

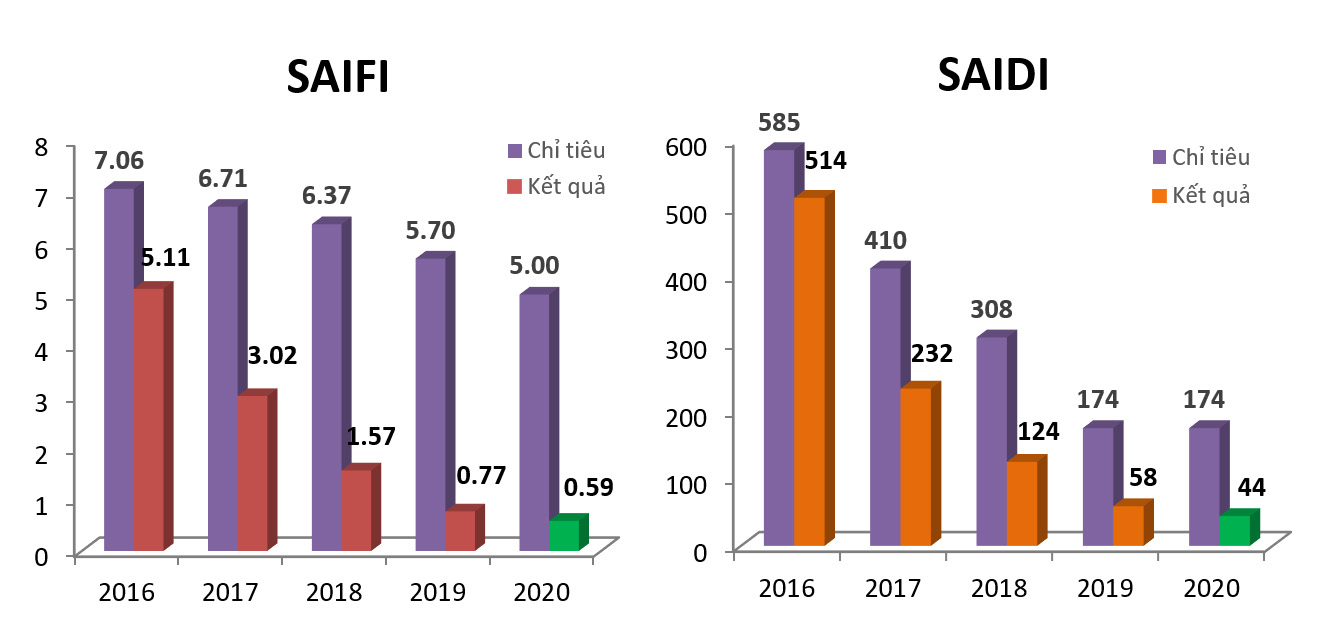

The improvement in EVNHCMC’s power supply reliability is best appreciated by considering the drop of its 2020 SAIFI and SAIDI compared to those of 2016. In 2016, the SAIFI was 5.11 times and SAIDI was 514 minutes; by 2020, they have decreased to 0.59 times and 44 minutes - an average reduction of 37.51% and 41.56% per year, respectively. This result, according to EVNHCMC, is achieved through implementing groups of actionable, synchronous solutions informed by the identification and exhaustive statistical analysis of every corresponding outage root cause.

EVNHCMC’s SAIFI, SAIDI from 2016 to 2020

EVNHCMC has also limited planned power cuts by investing in grid consolidation and the application of new power servicing techniques. Up to now, the 110kV power grid of Ho Chi Minh City has met the N-1 operational criteria, whereas central area power substations, in particular, have met the N-2 criteria; 100% of the 22kV medium-voltage lines are operating in a closed ring arrangement powered by two independent 110kV transformers. At the same time, EVNHCMC also promotes the application of live-line technology to minimize power cut duration: If in 2016, the number of live-line operations performed was just 3,839, by 2020, it was 14,400. These solutions combined lead to an annual decrease of 59.22% in planned outages. Equipment failure-caused outages are being addressed by adopting a comprehensive, end-to-end construction works quality management that encompasses material and equipment procurement, construction, maintenance, supervision, and acceptance. On the other hand, new technologies are intensively implemented such as CBM with diagnostic testing, automation with FDIR-based remote fault handling (in 2020, over 90% of service restoration tasks by remote load rerouting were completed in under 5 minutes). As a result, accidental failures were cut by an average of 38.1%/year.

To minimize outages caused by external violations of the grid protected right-of-way, an active communication channel has been maintained between EVNHCMC’s power companies and local authorities to collect information of works in construction with close proximity to power lines; on-site inspections have been conducted more frequently, up to 3 times per week, to prompt owners and contractors to fully deploy safety measures; the use of firework, firecrackers, metallic confetti cannons, and kites near power lines are discouraged through information campaigns made to local households and organizations; close coordination has been established with other relevant parties such as operators of road excavation works, water supply and drainage, telecommunications, lighting systems to provide underground cable, GIS drawings, and on-the-spot locating of underground cables to prevent digging into cables.

To mitigate impacts of power cuts for fire prevention and fighting purposes, EVNHCMC has deployed remote control devices to segment the power grid portions at fire-prone areas, thus medium voltage segments can be isolated without the need to switching off upstream circuit breakers, and subsequently, respective sites can be promptly approached and only low voltage facilities have to be isolated.

Implementing depth-oriented management of supply reliability, since 2020, EVNHCMC has supplemented its reliability assessment measures with the indicators of CAIFI (annual Customer Average Interruption Frequency Index) and CAIDI (Customer Average Interruption Duration Index) and accordingly assigned directive targets to its subsidiaries for implementation. In addition, by leveraging the comprehensive power failure statistical data provided by the Outage Management System, EVNHCMC can track all cases of customers experiencing outages more frequently or with longer durations to inform substantial remedial solutions.

EVNHCMC promotes the live-line working technique to minimize power cut impacts upon customers

EVNHCMC has announced a five-year business, investment, and development plan for the 2021-2025 period, in which it aims to improve the reliability of power supply with a targeted SAIFI of under 0.3 times and SAIDI of under 30 minutes. Strive for an Under-30 SAIDI in the 2021-2025 Period

Five groups of solutions are proposed by EVNHCMC to achieve these targets: Investing in construction; completing and developing the Smart Grid system; applying Industry 4.0 for digital transformation; promoting R&D, technology innovation and improvement; improving the quality of human resources.

Accordingly, EVNHCMC will implement Power Development Plan-based investments and construction to meet the load demand growth; consolidate the power grid structure to optimize management and operation following the principle of standardization, improving power supply reliability, ensuring the requirements for safety and urban aesthetics.

Simultaneously, the EVNHCMC will complete the construction of the backup Remote Control Center and modern operation centers for 100% subsidiary Power Companies; construct 5 to 10 digital substations of 110kV; pilot a Microgrid (small-scale smart grid) project for critical loads; research on the development of a shared information platform connecting applications of the Smart Grid.

EVNHCMC will also digitize the entire technical operation management and operation of the power grid; apply Condition-based Maintenance (CBM) while targeting the comprehensive Asset Management model; implement digital transformation through the study of core technologies including Big Data, IoT, AI, Data Analytics, etc. to effectively utilize the Power Sector database; develop applications to support decision-making in grid operation and management. Regarding working conditions, EVNHCMC will procure and deploy specialized and modern means and equipment for electrical construction and maintenance such as 110kV live-line working vehicles; compact medium voltage live-line vehicles that can operate in narrow alleys; pickup trucks with man lifts, specialized electric maintenance vehicles, electric motorcycles, etc.

EVNHCMC dedicates a special effort in building professional capacity for technical workers in operating construction machinery, instruments, tools, and personal protection equipment (PPE), operational and professional skills, professional working ethics and corporate culture; organizing specialized training courses in key fields such as automation, advanced repair and maintenance, Industry 4.0, etc.

evn.com.vn

Share